Manufacturing & Mechanical Design

Engineering Solutions Delivered

This portfolio showcases a range of projects where we applied meticulous mechanical design, advanced simulation, and DFM/DFA principles to solve complex challenges and deliver tangible results for our clients.

We categorize our projects to quickly demonstrate our versatility across different engineering disciplines:

1. High-Efficiency Material Handling System: Belt Conveyor

We designed a robust, standardized conveyor module using FEA (Finite Element Analysis) to optimize the frame structure, reducing steel usage without compromising strength. We incorporated a tensioning mechanism for quick belt alignment and specified high-efficiency drive components. The final design resulted in a 15% reduction in material weight (cost savings) and an estimated 20% decrease in required maintenance time due to the simplified, accessible component layout.

3. Contaminant Removal System: Industrial Magnetic Collector

Overband magnets are self-cleaning systems with a separate belt that continuously runs around the body of the main magnet. This design automatically and continuously removes captured metal from the magnet face, discharging it into a separate chute or bin.

2. Separation System: Rotary Trommel

We designed a trommel screen (a rotating cylindrical sieve) that could efficiently separate mixed municipal waste at a capacity exceeding 100 tons/hr. Key design features included: Structural Integrity, Drive System and Maintenance Focus.

4. Specialized Fluid Storage: Industrial Fuel Tank

Our team conducted detailed structural analysis (FEA) on the tank shell and support saddles to withstand required pressures and external loads. We designed access ports and venting systems compliant with safety regulations and provided complete fabrication drawings including weld procedures and inspection points.

Other Customize Designed Elements: Heavy-Duty Steel Gates, Lighting poles, Steel desks and beds.

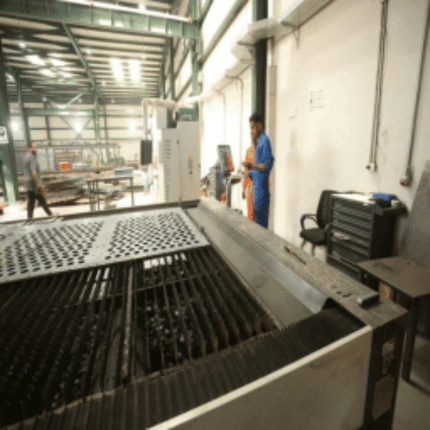

Production Line and Spare Parts Plant

ECWM specializes in providing tailored solutions for municipal solid waste treatment and recycling, as well as disposal. In addition, ECWM managed to develop tailored MSW solutions for treatment and recycling. In cooperation with Untha and Westeria, ECWM manufactures the complete treatment and recycling lines at their plant, in addition to manufacturing wear and tear spare parts locally. The manufacturing of the tailored solution is based on waste quantity and characterization, and includes:

Defining the product concept and designing it in detail using computer-aided design (CAD) software.

Identifying and purchasing the most suitable raw materials for the product in terms of quality and reliability.

Produce finished parts through various processes such as cutting ,forming, and machining.

Assembling the various parts and components to form the final product.

Inspecting the final product to ensure conformance to the required specifications and standards.

- Since In today's highly competitive industrial market, it has become essential for any plant or corporation to keep pace with developments and continuously upgrade its production lines. Upgrading and developing production lines does not only increase efficiency and quality, but also reduces costs and helps to achieve maximum productivity.

Production Line Manufacturing, Modification & Upgrading

We design, build, and enhance production lines to improve efficiency, reliability, and output quality.

- Production line manufacturing, modification, and upgrading

- Contract manufacturing

- CNC laser cutting

- Generic lathing

- CNC milling

- Spare parts manufacturing

- Metalworking

We use the latest equipment and modern manufacturing technologies in our manufacturing plant

At ECWM, we rely on the latest equipment and modern manufacturing technologies to ensure precision, efficiency, and world-class quality across all production stages. Our factory is equipped with a comprehensive range of advanced machinery designed to serve diverse industrial applications.

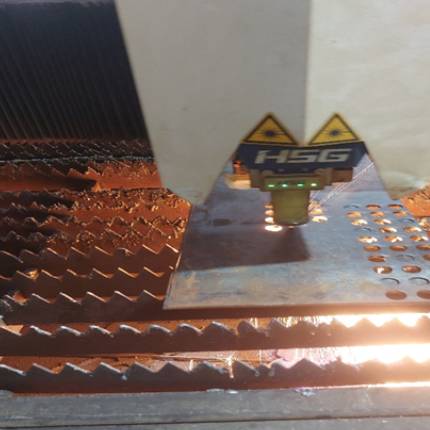

CNC Laser Machine

In the rapidly evolving field of metal processing, laser cutting machines stand out for their precision, versatility, and efficiency, as they are used for cutting, engraving, and drilling a wide range of materials with high accuracy.

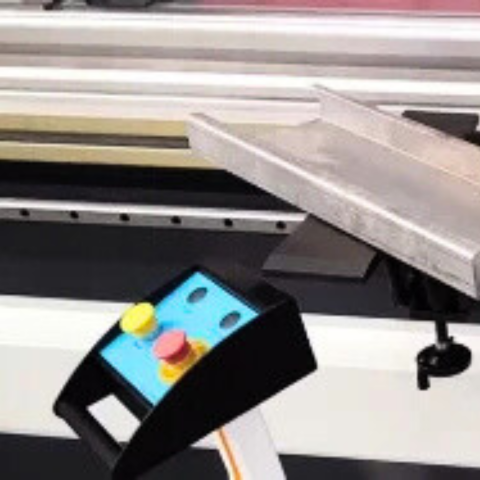

Sheet Metal Rolling Machine

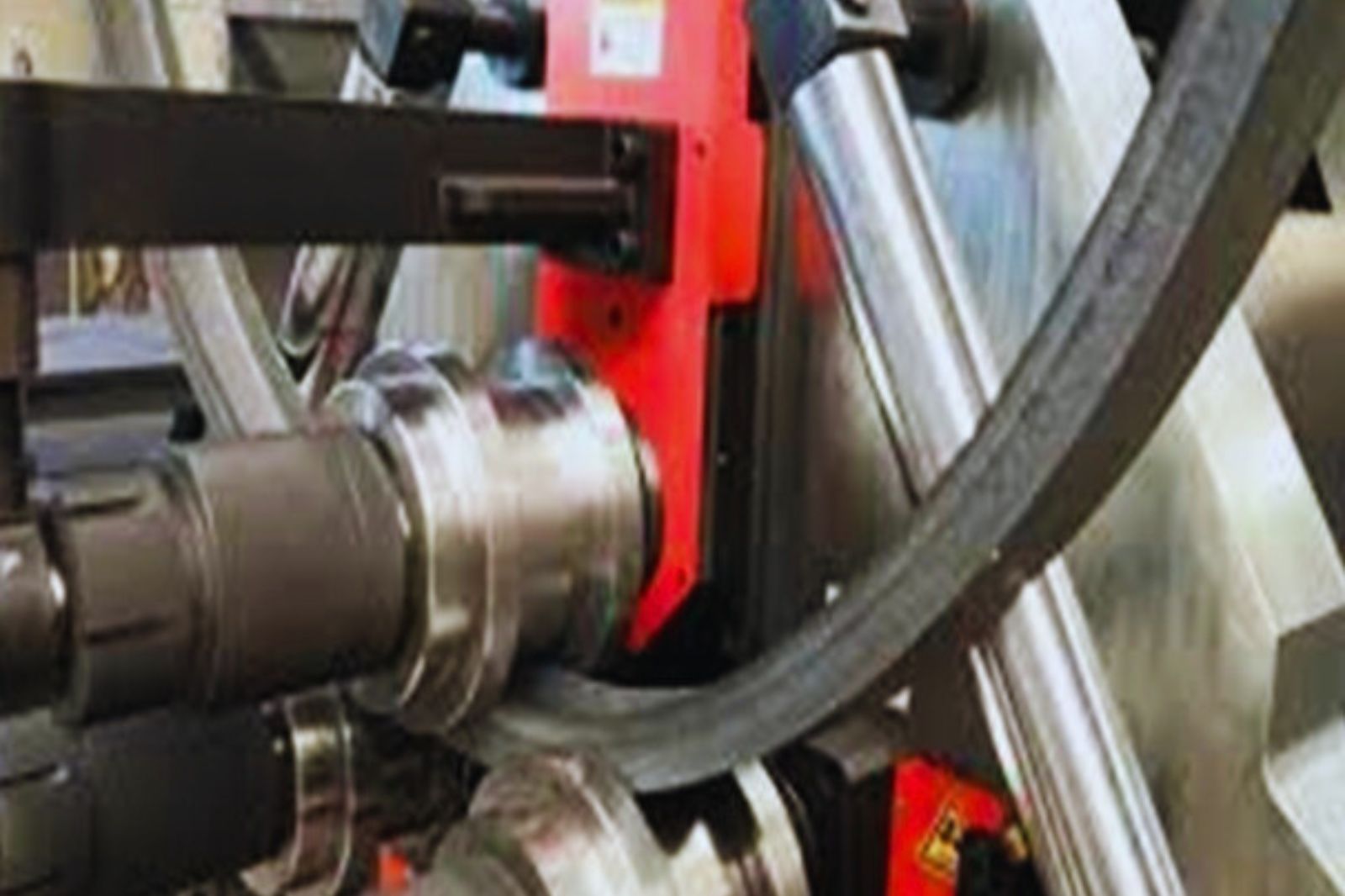

Corner Bending / Angle Rolling Machine

Also known as a section bending machine, it is used to form angles, pipes, square and rectangular sections into curved or circular shapes.

This machine is vital for industries that require precisely curved metal components for structural or mechanical applications.

Lathe Machine (Turning)

Turning is one of the most critical metalworking processes used to produce high-precision, consistent components such as shafts, screws, bushings, and discs.

Our modern lathes ensure accuracy, repeatability, and smooth surface finishes needed for high-performance industrial systems.

Finishing, assembly, transportation, and installation

The Deputy Prime Minister and the Minister of Local Development in 10th of Ramadan City in August 2025.

The Deputy Prime Minister and the Minister of Local Development visit and review the waste management complex in 10th of Ramadan City in August 2025.

They reviewed the machines and operation process at the facility and listened to a detailed explanation of the facility’s operation works, and compliance with the technical standards for producing waste recycling and treatment production lines